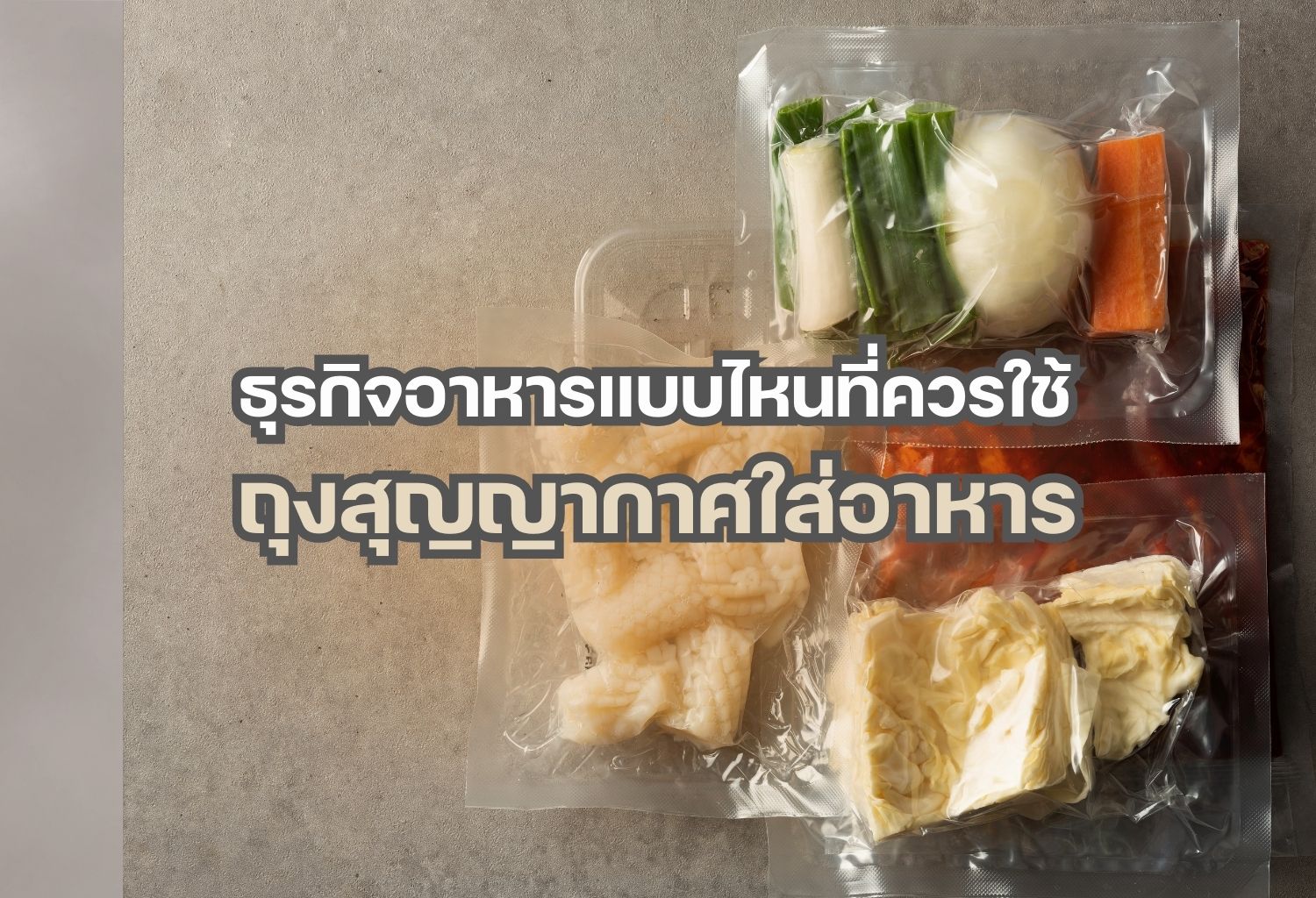

Which food businesses should use vacuum food packaging

At present, vacuum food bags are one of the most popular packaging solutions in the food industry. They help extend shelf life, reduce contamination, and maintain food freshness for longer periods. As a result, many food businesses adopt vacuum food bags as part of their packaging process to add value to their products and remain competitive in the market.

If you are a food business owner looking for a factory to produce vacuum food bags, it is important to understand which types of food businesses are best suited for this packaging and why choosing a certified manufacturer is essential. High-quality vacuum packaging can enhance sales, increase credibility, and strengthen your brand image.

Which Types of Food Businesses Should Use Vacuum Food Bags?

1. Frozen Food Businesses

Vacuum food bags are ideal for preserving frozen food quality. They help prevent frost formation and freezer burn, which are common issues with standard packaging. Vacuum sealing also prevents discoloration of meat and preserves flavor.

Suitable products include:

-

Frozen meats such as pork, chicken, beef, and fish that require long-term quality preservation

-

Frozen seafood such as shrimp, squid, and shellfish, which are delicate and easily deteriorate when exposed to air

-

Ready-to-eat frozen meals such as lunch boxes and curry packs that need to retain fresh-cooked taste

2. Processed Food Businesses

Processed foods benefit greatly from vacuum food bags as they help slow deterioration and preserve flavor over extended periods—especially important for export and long distribution cycles.

Common examples include:

-

Sausages, ham, and bacon that require freshness and flavor retention

-

Meatballs and fermented pork products prone to moisture and bacterial growth

-

Dried meats, shredded pork, and sun-dried beef that require mold prevention

3. Ready-to-Eat Food Businesses

Ready-to-eat meals require packaging that maintains taste and freshness while minimizing contamination. Vacuum food bags are ideal for:

-

Ready meals that must be stored longer without flavor loss

-

Chilled foods such as salads and chili pastes that need freshness and bacterial safety

-

Foods requiring reheating such as soups and stews, where texture and flavor retention are critical

4. Healthy Food Businesses

Healthy food segments—such as clean eating, keto meals, and high-protein foods—require packaging that preserves nutritional value and freshness. Vacuum food bags reduce oxidation and bacterial contamination while offering convenience for storage and distribution.

5. Restaurants Seeking Cost Reduction and Efficiency

Restaurants can use vacuum food bags to store ingredients longer and prepare food in advance, improving operational efficiency and reducing waste.

Examples include:

-

Storing raw meats before cooking to maintain freshness

-

Preparing sauces and broths in advance for faster service

-

Storing cooked food for next-day use to reduce preparation time and costs

Why Order Vacuum Food Bags from a Certified Manufacturer?

Choosing a qualified manufacturer ensures durable, safe, and food-grade packaging. Certified factories typically offer:

-

Food-grade materials safe for direct food contact

-

High-quality flexible plastics resistant to pressure, leaks, and tearing

-

Manufacturing standards such as GMP and HACCP to ensure safety

-

Capability for large-scale production and customized designs

Order Vacuum Food Bags with Us

If you are searching for a trusted manufacturer of vacuum food bags that meet food safety standards and your business requirements, we are your packaging partner.

-

High-quality materials using strong, flexible plastics

-

Custom production options for size, thickness, and bag type

-

International manufacturing standards suitable for all food categories

-

Factory-direct pricing to help reduce business costs

Contact us today for consultation and a quotation.

Let vacuum food bags support your business growth, extend food shelf life, and enhance product value. Quality packaging starts with a reliable manufacturer.